I had great plans for this weekend. I long list of things that I was planning on doing. The weather had other plans. This summer has really not been suited to outdoor boatbuilding. It's been best suited to getting on a plane and going somewhere else.

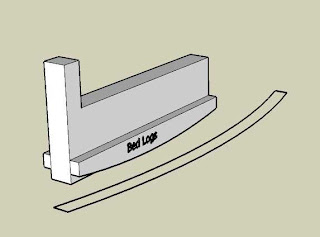

I did get some work done, I had to plane a simple Oak batten to fit between two plywood gussets, The slats for the seats will screw into these battens. Given that I had gone to the trouble of buying some decent blades for my planes and some waterstones and then going to the trouble of reading all about sharpening, I thought I'd leave the Bosch in its box and break out the Stanley.

The blade was sharp, bald patch on my arm sharp. Gillete eat your heart out. I set the plane to take very thin shavings and started. I had to take about 3/16 of an inch off the batten to make it fit, and I had to square it up a little.

Damn, It's hard work. Oak is hard stuff, and I had the "benefit" of trying to do this on a fold up work bench, so I had to use my weight to hold the bench steady and my arms to plane. I gather that with a proper bench you get to use your body weight to do the planing.

I found that Oak will blunt a blade quite quickly, you can feel it getting harder and harder to push the plane, and you find the shavings concertina. This is a good indication that 30 seconds on the waterstone is required, sacrifice some more hair from my arm to the Sharp Gods, and off we go again.

It was a great experience to square and thickness the wood the old fashioned way, but I will admit to dragging out the Bosch in order do the second batten, in about 1/10th of the time.

When you look at pictures of old wooden sailing ships, and think that they didn't have Bosch, Makita, or even Black and Decker, you start to look at them in a different light.

Oh yes, and never try a crushing handshake on someone who actaully uses a hand tools for a living.